New Release Announcement

Bicycle Motor Works spent several months with Penn State’s Engineering Capstone Team, as they were tasked to develop a custom eBike Battery Mounting System, that improves our production process, upgrades our pack’s encasement, streamlines turnaround time and delivers a structurally sound system designed to adapt to a multitude of mounting preferences. This video is our team’s final presentation, taken during the Capstone Design Project Showcase at Penn State University on April 25, 2023. We would like to thank Penn State’s Engineering Capstone Team, PennTap, the Learning Factory and everyone involved to make this happen! Our team was amazing! More updates to be announced. View the full presentation, unedited version.

The Team’s Final Reveal

STAY TUNED FOR UPDATES ON THE LAUNCH OF OUR NEWEST SERIES!Â

A very special thanks to:

Our amazing Engineering Team, meet our Team Members.

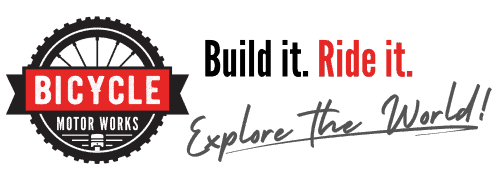

The Survey Results

Learn why CYC’s Gen 3 out ranks all other e-conversion bike systems on the market to-date!

READ MORE.

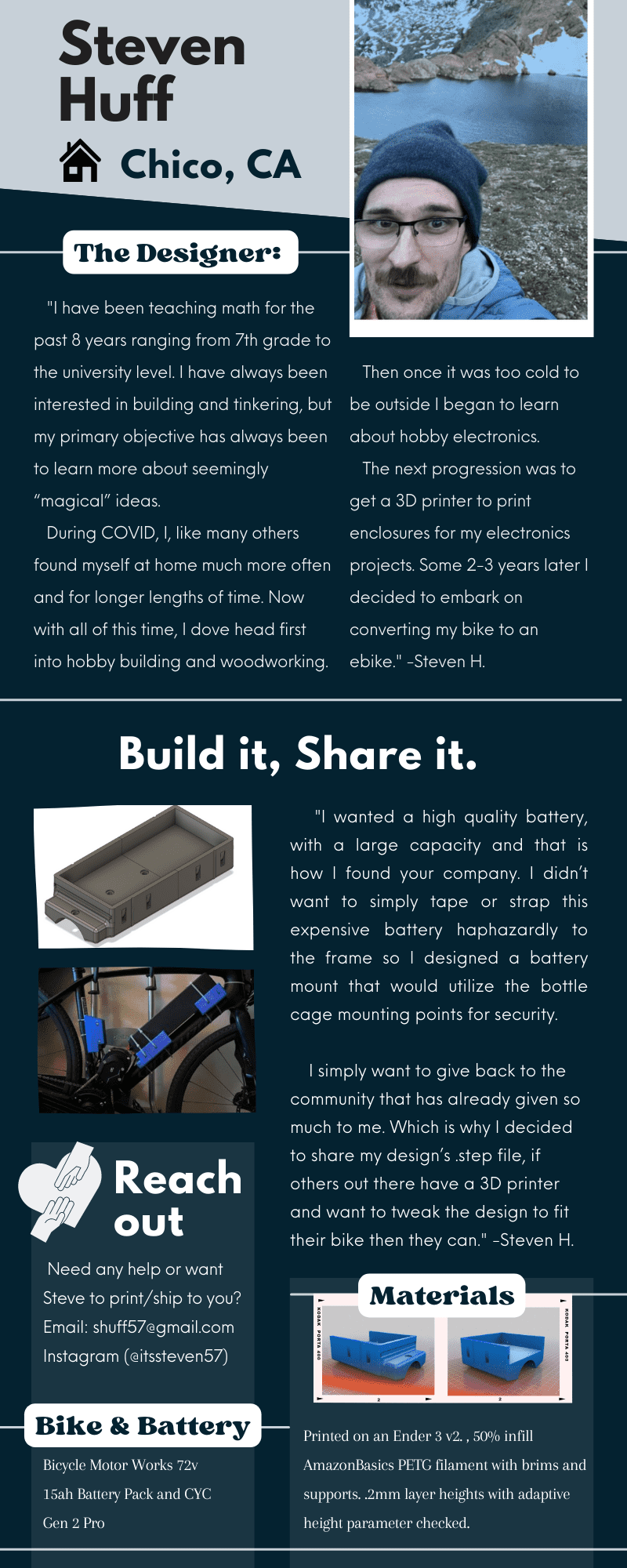

Build Your Own E-Battery Mount

If you have a 3-D Printer, you can build your own E-Bike Battery Mount for FREE. Don’t thank us, we can only provide you the files.

Learn more about the E-Bike Battery Mount and read about the Creator below.

» Learn More About E-Bikes:

E-Bike Battery 101

Learning the Basics on Lithium-ion Batteries [...]

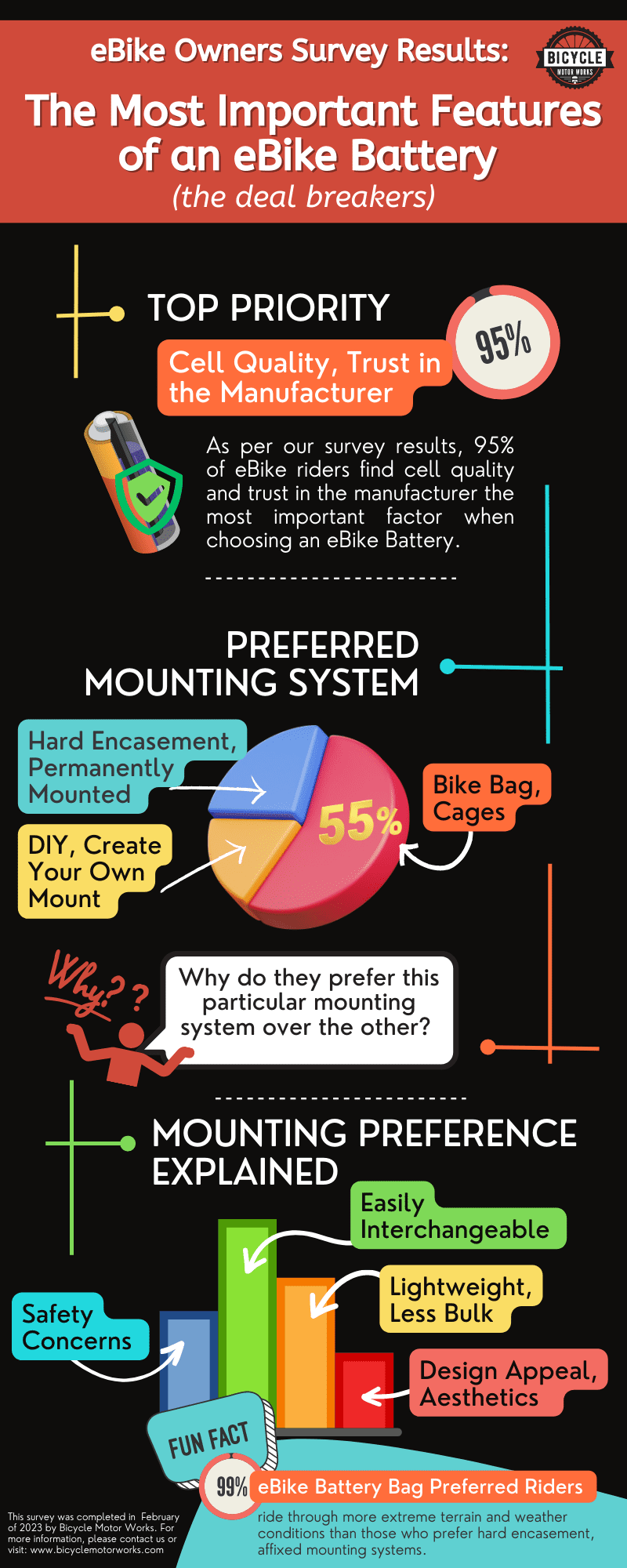

We value quality. Learn how we build it.

The Ultra-High Power Cell

Learn more about MOLICEL.

eBike Rebates

Get the list.

A Message From Our Friends …

Other News:

eBike Rebate Programs

SF Bay Area - Clunker [...]

E-Bike Battery Tip from Keith

E-Biker Builder: Keith hello, from Hawaii [...]